These

are some of the main components of the 1:20 scale Elizabeth

Swan technology demonstrator. We applied for part funding

for this project from the Dti's marine technology

competition. But, they said they were concerned about

cleaning of the panels of salt caking at sea, as applied to

ships. We have solved that problem, and were prepared to

share that information in return for helping us with

development costs. We considered the automatic furling and

sun tracking to be an important feature for applications

like cargo ships, cruise liners and ferries - not so the UK

government. But then, we suppose that most governments

around the world are in a pickle. Looking for ways to power

ships to meet with the IMO's zero targets for 2100 without

much modification of hulls and decks. The target for 2030 is

a 40% reduction in GHG emissions. The Elizabeth Swann is a

clean-sheet-of-paper design. Not flavour of the month with

fleet operators, as well we appreciate. But then progress is

sometimes financially painful. In the commercial world it is

all about profits. Now, the planet gets a look in, but still

has to wait for existing ships to depreciate. We have

suggested a scrappage scheme is applied to induce ship

operators to change out hulls earlier, as was applied to

cars some years ago.

INTERNATIONAL

MARITIME ORGANIZATION (IMO)

- NET ZERO TARGETS

Under their identified “levels of ambition”, the

IMOs initial Green

House Gas (GHG) strategy envisages, a reduction in carbon intensity of international shipping (to reduce

CO2 emissions per transport work, as an average across international shipping, by at least:

40% by

2030, pursuing efforts towards

50% by

2040, and that total annual GHG emissions from international shipping should be reduced by at least

70% by 2050

and then

100%

by 2100 ( compared to

2008 levels)

We

should not be complacent about the looming 2030 target. It

is very easy to put things off; oh it will be okay if we

leave it another couple of years. Somebody else will come up

with the solution. Really! If that was true the EU (Horizon

Europe) and UK would not be pumping billions of Euros

into ZEWT

research. As we have amply demonstrated over more than three

years joining consortiums and making applications for RI

funding, SMEs do not get a look in on the large sums of

money being gifted to large corporations. Hence, the speed

of clean shipping development rests on big shipping concerns

and the universities, who work for those concerns.

We

imagine that huge fines will be imposed, and possibly ship

confiscations in ports, in the event of persistent

offenders. At that point, you can imagine a mad scramble to

buy clean replacements. But, why leave it that late, and why

put your cargo and transport business at risk.

If

we can do it on a shoestring budget, the professionals can

easily change over to zero emission technology. It may even

be cheaper in the long run, with reduced fuel costs. Imagine

that. Goods being delivered for less. It is probable that

once fossil fuels are phased out, cars, homes and factories

will be cheaper to operate. It should represent a giant leap

in the direction of world peace. With food

security next on the list of problems to be solved.

Perhaps, with ZEVs, the oceans will be less

acid, and fish

stocks might slowly recover.

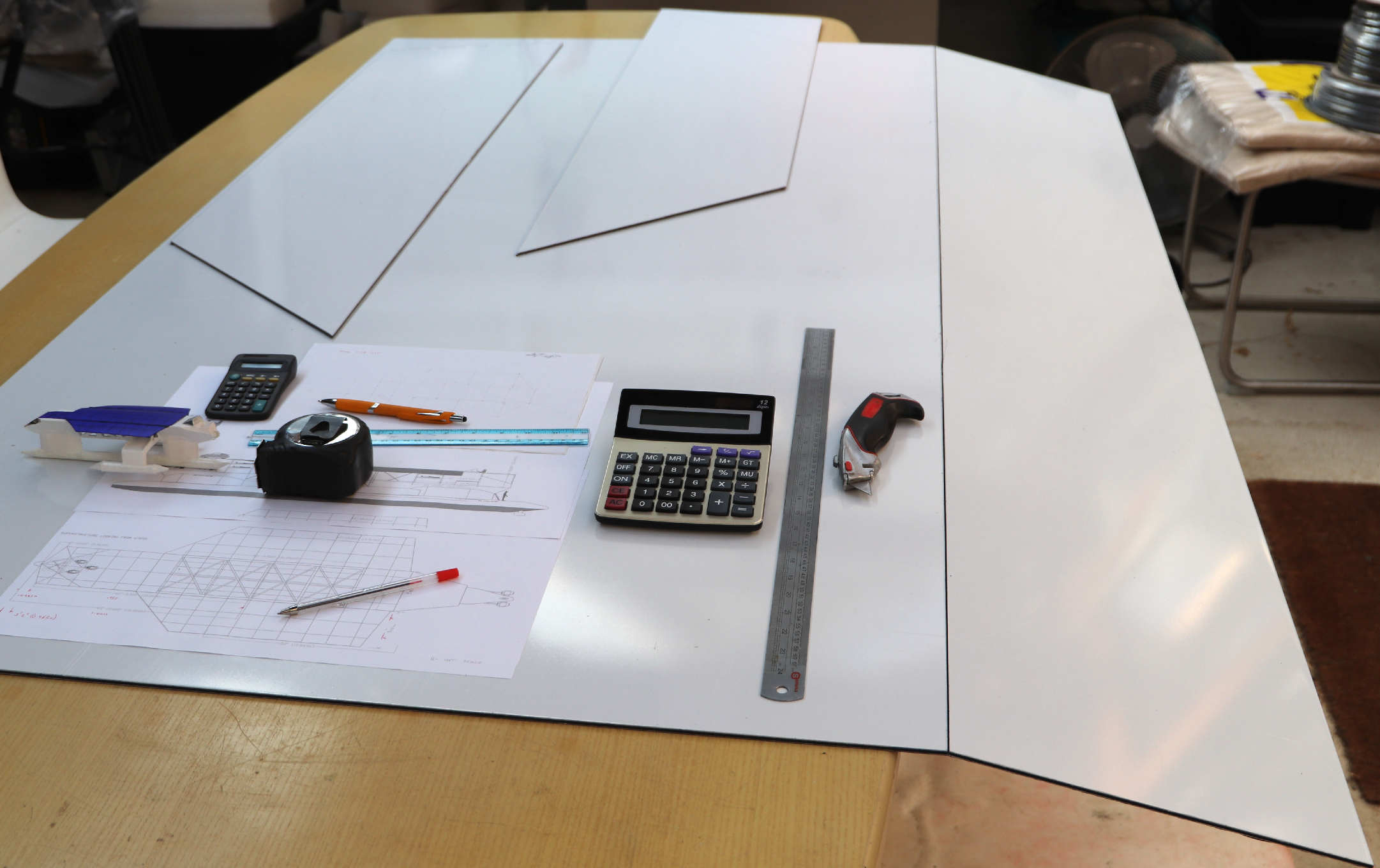

We

used a sheet of aluminium sandwich, with dense foam core,

that is conveniently white on both sides. One 8' x 4' feet

sheet was sufficient. The supplier was amazingly fast in

delivering - should we need any more. Cutting this material

takes a bit of getting used to. You'll need a large worktop

or table. The aluminium is scored multiple times with a

sharp steel blade, as in a Stanley, or other similar make of

knife. It is better to work from one side only. Once through

the first skin. apply downwards pressure to cut through the

interlayer, and score the underside of the other alloy skin.

Then bend, and the sheet will part cleanly. Be careful

though, our tutor cut himself on the sharp alloy edges. And

Stanley knives are very dangerous if misused. Wearing

protective gloves is a good idea.

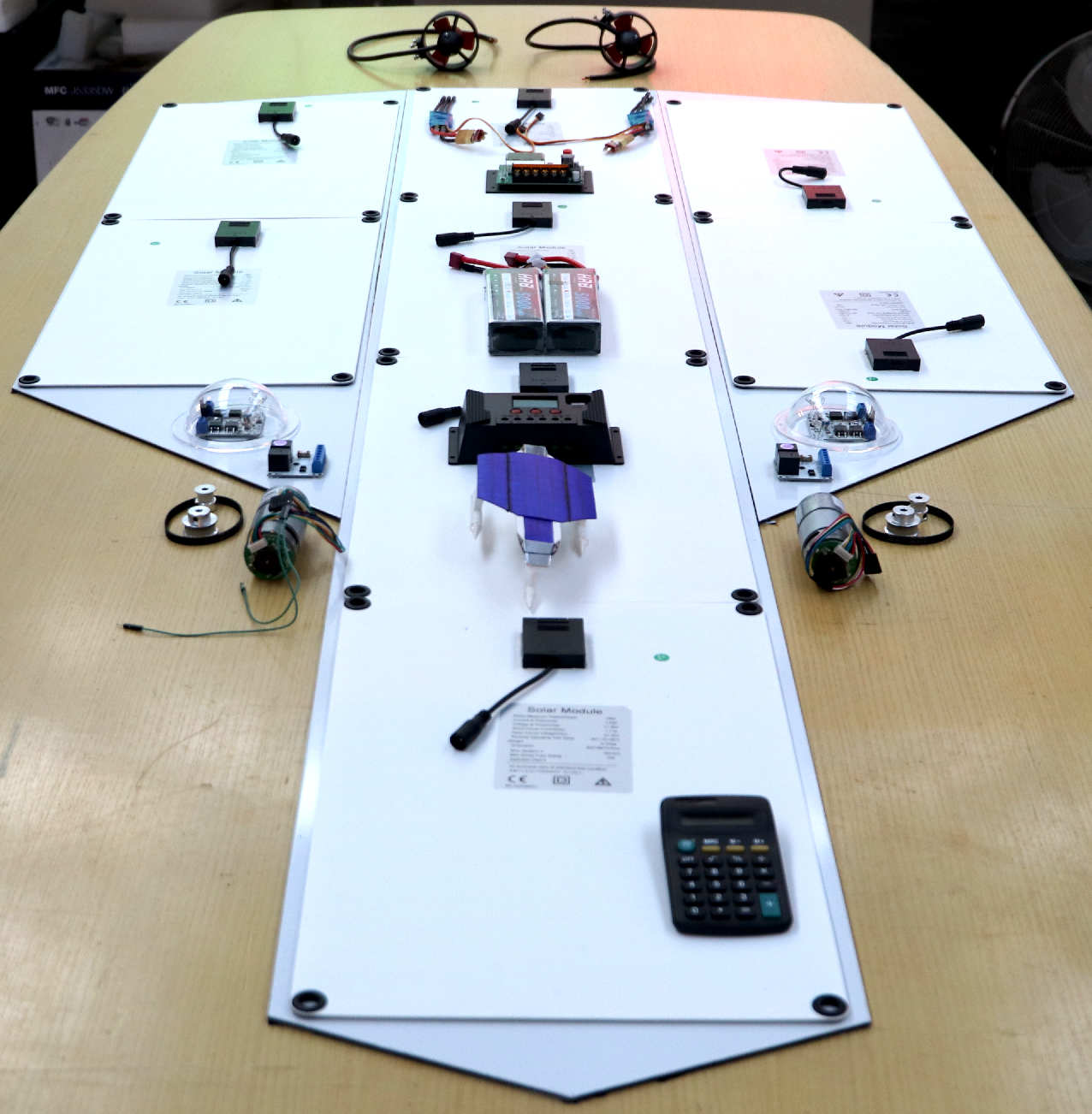

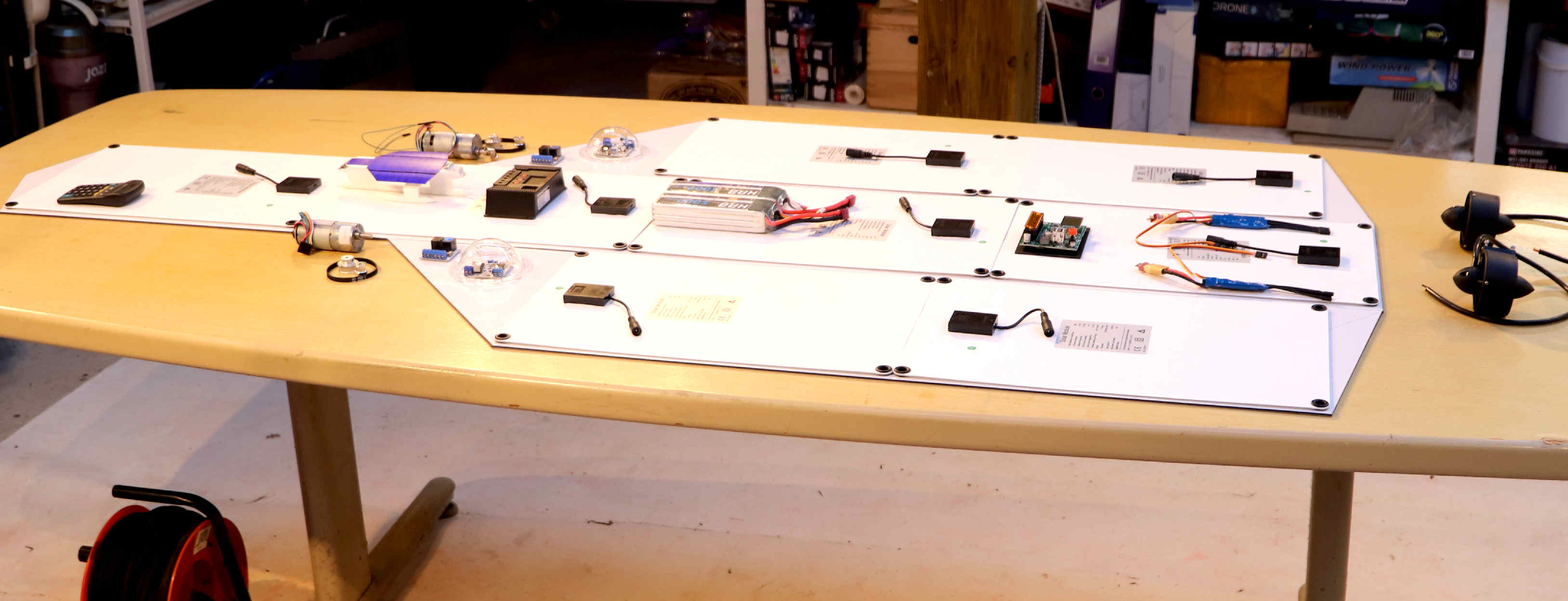

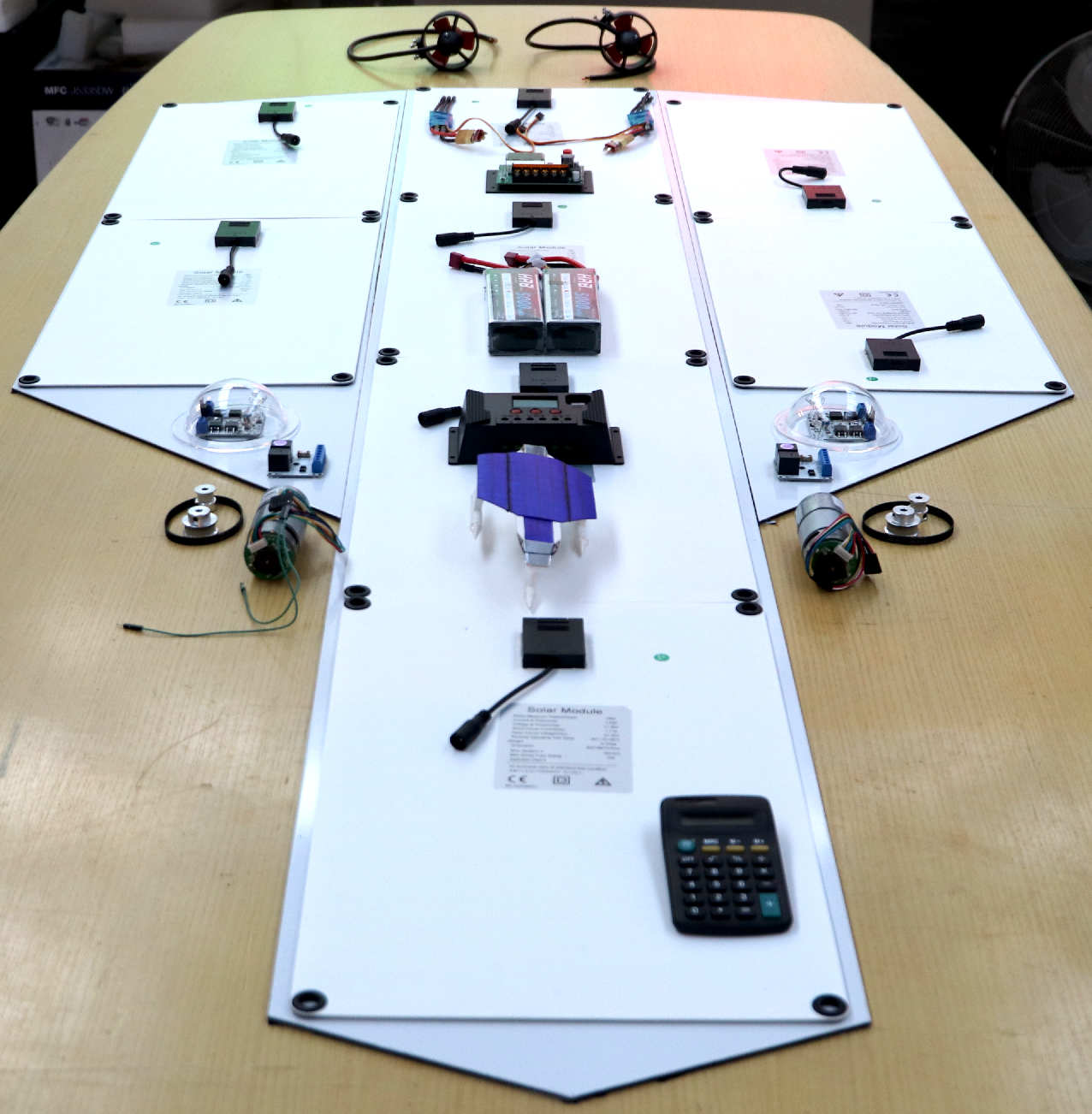

With

the three main parts cut: 2 x wings and 1 x deck area, we

laid out the solar panels and other electronic and

electrical parts to simulate the position on the completed

model. Most satisfying - it all fits. In fact, the design

had to be modified to allow fitment of standard size 18 volt

solar panels. These are mostly used on cars and mobile homes

to charge laptops and power TVs. The solar panels charge two

lithium batteries, via a charge controller. In this picture

you can also see the motors that rotate the solar wings to

face the sun, and the sensors that measure the angle of

insolation (incoming solar radiation), to switch the motors

on and off, as required for tracking purposes. You can also

see the thrusters and speed controllers on the far right. As

you may notice, we've shoehorned 8 x 18 watt solar panels

onto the active deck area, for a total of 144 watts. Meaning

a cruising power of roughly 65 watts 24/7.

Fortunately,

our directors were able to stretch to the purchase of the

above components, by way of trustees loans to the

Foundation. In addition, another charitable Trust felt

compelled to provide workshop space and cover the operational

overheads. Lastly, a local model maker agreed to tutor home

schooled students, without charge. This saved the Foundation

approximately £16k. We'll still need to find funding for

transport and events - as part of the ocean and climate

awareness campaign.

We

might be able to modify the stand used for SeaVax

exhibitions - and that will save more money. Imagine the

development cost if this was an MOD

project.

A

view of the main solar harvesting, tracking, and motor

propulsion components, with the vessel cruising toward you.

We have already had to modify the design, increasing the length

by nearly four meters, over the full size vessel (pro rata).

Hence this special effects model is around 2.4 meters long.

The full size vessel is just under 48 meters. The original

design is 44 meters.

THE

MAIN COMPONENTS OF THE ELIZABETH SWANN

Hull. The hull of any water vessel is the most

important part of the boat or ship, onto which is attached

the thrusters and rudders or other directional controls. It is the most important part of any design.

Superstructure.

This frame and cabins, provides a structure to attach the

solar wings, camera, lights, and other components of our

model.

Thrusters. The thrusters are electrically or hydraulically powered propellers used to maneuver the vehicle. There are almost always multiple thrusters to provide movement in multiple directions.

Solar

Wings. As this model is powered with free energy from

nature, it is autonomous, not needing shore based charging,

or fossil

fuels. Moveable wings allow the solar panels to change

position to face the sun while on the go, so harvesting more free energy

than a ship with fixed deck panels - making it faster. In addition, having

wings that fold, makes the model, and full size ship, safer

in stormy conditions. Testing in winds will be one of a group of experiments, in a specially equipped test tank.

Pilot Controls. The surface controls can range from something that looks like the control room for a spaceship to something as simple as a

smartphone, or an Xbox game controller. The surface controls provide a physical interface for the pilot to control the vehicle and a display of feedback from the vehicle including the camera view.

Camera. Since the vehicle travels over the water, and

to be able to record performance or provide media streaming,

we are including an onboard camera, which must be able to provide an image with low-latency.

Lights. The lights provide illumination for the camera

(hence operator) to see in reduced light conditions.

ROVs

or UUVs - Are generally smaller unmanned underwater vessels,

than their crewed counterparts,

without life support, making them cheaper to build and

operate. Much of the technology of these large submersibles

is shared with the Elizabeth Swann.