The

'Elizabeth Swann' cruising along the Amazon,

seen here in normal low-drag (displacement) hull mode, with

her solar wing panels tilted down on both sides, about 30 degrees from horizontal.

This vessel can fly on foils using hydrogen to boost thrust

for take-off, if the occasion demands, though mostly cruises

on solar power as wave piercing hull.

The

Elizabeth

Swann is a hydrofoil

design, where the underwater wings may be retracted to

reduce draft in shallow waters. Her electric

waterjet drives also increase the efficiency of the

propulsion system as opposed to traditional ship, open revolving propeller

designs.

These

features, allow the Elizabeth

Swann to travel greater distances at higher speeds,

using less green

hydrogen (derived) fuel and solar energy.

As

with other ocean going hydrofoil

vessels, a good object detection system is needed to

ensure that the sub-surface wings are not damaged. A good

example of yacht racing technology, turned to practical

commercial use, is the Artemis workboats and crew transfer

vessels, featured below.

The Boeing 929 Jetfoils are passenger-carrying, waterjet-propelled hydrofoils. Boeing adapted many systems used in jet airplanes for hydrofoils. Robert Bateman led development. Boeing launched its first passenger-carrying waterjet-propelled hydrofoil in April 1974. It could carry from 167 to 350 passengers. It was based on technology developed for the U.S. Navy patrol hydrofoil Tucumcari, and shared technology with the Pegasus class military patrol hydrofoils. The product line was licensed to the Japanese company Kawasaki Heavy Industries.

The displacement is 115 short tons (104 t), with dimensions: Length 90 feet x Beam 18 feet x Draft 4 feet 6 inches to 6 feet 6 inches

(foilborne) Depth 3.0 m. Propulsion is by 2 x Rolls-Royce Allison 501KF Gas Turbine engines, giving a speed of 40 to 45 knots (46 to 51.8 mph), with a 4 to 8 man crew.

Boeing launched three Jetfoil 929-100 hydrofoils that were acquired in 1975 for service in the Hawaiian Islands, which was operated by a Honolulu-based operator Seaflite. Seaflite operated three Boeing 929-100 Jetfoils between 1975 and the company's demise in 1979. When the service ended the three hydrofoils were acquired by Far East Hydrofoil (now TurboJET) for service between Hong Kong and Macau. About two dozen Boeing Jetfoils saw service in Hong Kong-Macau, Japan, South Korea, the English

Channel, the Canary Islands, the Korea Strait, Saudi Arabia and Indonesia.

In 1979, the Royal Navy purchased a Boeing Jetfoil, HMS Speedy, to provide the

senior service with an opportunity to gain practical experience in the operation and support of a modern hydrofoil, to establish technical and performance characteristics, and to assess the capability of a hydrofoil in the Fishery Protection Squadron.

In 1980 B&I shipping lines opened a Jetfoil service from Dublin to Liverpool with the jetfoil Cú Na Mara (Hound of the Sea). The service was not a success and was discontinued at the end of the 1981 season.

The Belgian Regie voor Maritiem Transport (RMT) operated the jetfoils Princesse Clementine and Prinses Stephanie on the Ostend-Dover route from 1981 until 1997.

In North America, the Boeing Jetfoil saw regularly scheduled service between Seattle, Washington, and Victoria, British Columbia, during the summer tourist season of 1980. Leased from Boeing, a single Jetfoil, the Flying Princess, was operated by the non-profit Flying Princess Transportation Corp., with the close co-operation and assistance of the B.C. Steamship Company. Regularly scheduled service ran from Seattle to Victoria to Vancouver from April to September, 1985, by Island Jetfoil.

A

BIT OF HISTORY

Ships that use hydrofoils, or foils, are themselves called hydrofoils. Hydrofoils can lift a boat’s hull clear of the water as speed increases, and the resultant reduction in drag yields higher speeds without expending more

horsepower.

The two main foil systems now in use are the surface-piercing and submerged types. Surface-piercing foils just break the surface of the water and are usually arranged in a

'V' shape.

They tend to produce more wash, which translates to drag.

Foils that stay fully submerged project down into the water vertically. When at rest or steaming slowly, a hydrofoil ship supports its weight

from its own buoyancy, but as speed is increased, the foils carry progressively more weight until the ship’s hull is raised clear of the

water. Hydrofoil ships are faster than ships of conventional design but are limited to moderate sizes.

GIANNI M - When the 165-ton Supramar PT.150 appeared in 1968 it was the largest commercial seagoing hydrofoil in the world. Almost forty-seven years later it still is, in terms of displacement.

On March 24 2016, the first Admiral 350 hydrofoil, dubbed the world’s largest

hydrofoil, was officially launched in a ceremony at the HSC Shipyard at Trapani in western Sicily. Attending were, among others, city and regional authorities and VIPs as

well as of course executives and workers of both the shipyard and Ustica Lines, headed by managing director Ettore Morace. The customary smashing of a bottle of champagne onto the hull of the grand hydrofoil, Gianni M, was executed by its godmother Simona Vicari, secretary at the Ministry of Infrastructure and Transport.

The vessel has cost in the region of €7 million to design and build, a portion of this sum being EU funds. The development has been carried out by HSC in collaboration with the

engineering faculty of the University of Palermo. The 155-ton, 38m, 350-passenger Gianni M is not the largest hydrofoil ever built, but it is certainly the largest commercial craft completed and active since 1986.

Power is supplied by a pair of 2,300kW engines positioned midships expected to offer a cruising speed of 37 knots and maximum speed of 38 knots. The range is 600 nautical miles. Passenger

accommodation is on three levels. Adjacent to the wheelhouse is a saloon seating 40, the main deck forward and aft saloons seat 80 and 68 passengers, respectively, and on lower deck the forward and aft saloons seat 82 and 76 passengers. There are four toilets on main deck and one in each saloon on lower deck. Two double

doors port and starboard on main deck secure easy and effective access and

Disembarkation.

The first efficient manned hydrofoil ship was built in Italy about 1900 by Enrico Forlanini. Hydrofoils were not widely used until the 1950s, when military and commercial models were built.

Even though navies shy of tech in preference to heft of

carriers, but soon reverted. By the 1970s hydrofoil craft were in operation in many places, and speeds of up to 80 knots (nautical miles per hour) had been

achieved with operational cost savings. It is difficult to

imagine a nuclear powerplant on wings. Submarines already

fly underwater (small) with bow, sail and stern planes.

Being buoyancy neutral submerged.

Another configuration that is generally preferred currently is the T-type. The hydrofoils are just connected perpendicularly to the hull & completely submerged in

water.

Since the foils are completely submerged, turbulences and waves don’t

rock (pitch) the boat and one could enjoy a smooth ride! However, when it comes to and rolling movement, T-type foils are not self stabilising. Hence, a mechatronic control system changes the angle of attacks of each foil accordingly to maintain the smoothness.

In the early 1900s Alexander Graham Bell (inventor of the telephone) with his chief engineer, Casey Baldwin started experimenting & testing models based on designs of Forlanini.

Upon his request, the US Navy granted him two 350hp engines for his hydrofoil watercraft HD-4. In September 1919, the HD-4 set a

world marine speed record of 114 km/h(71 mph), which stood for 2 decades.

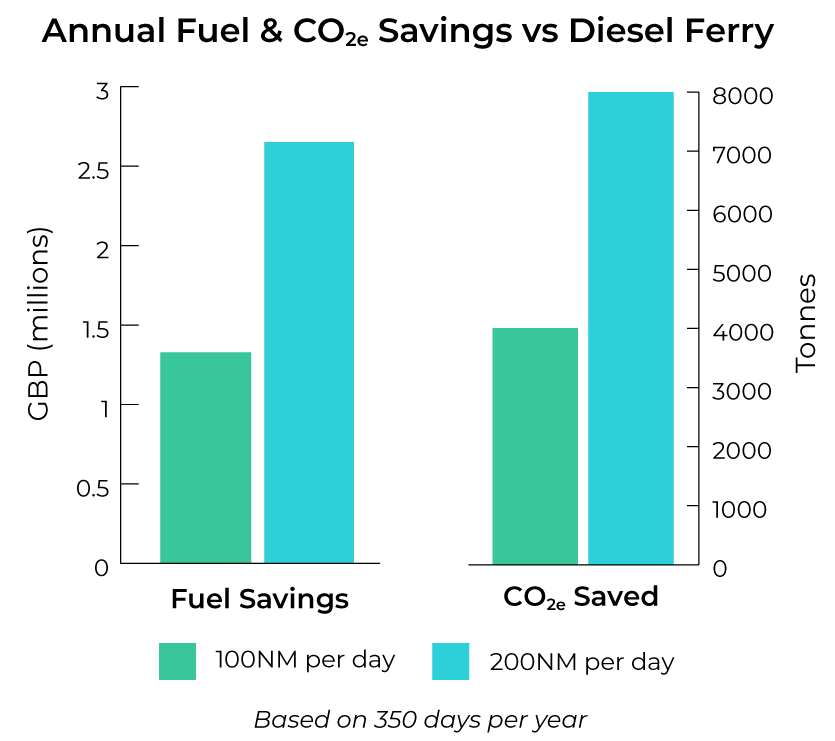

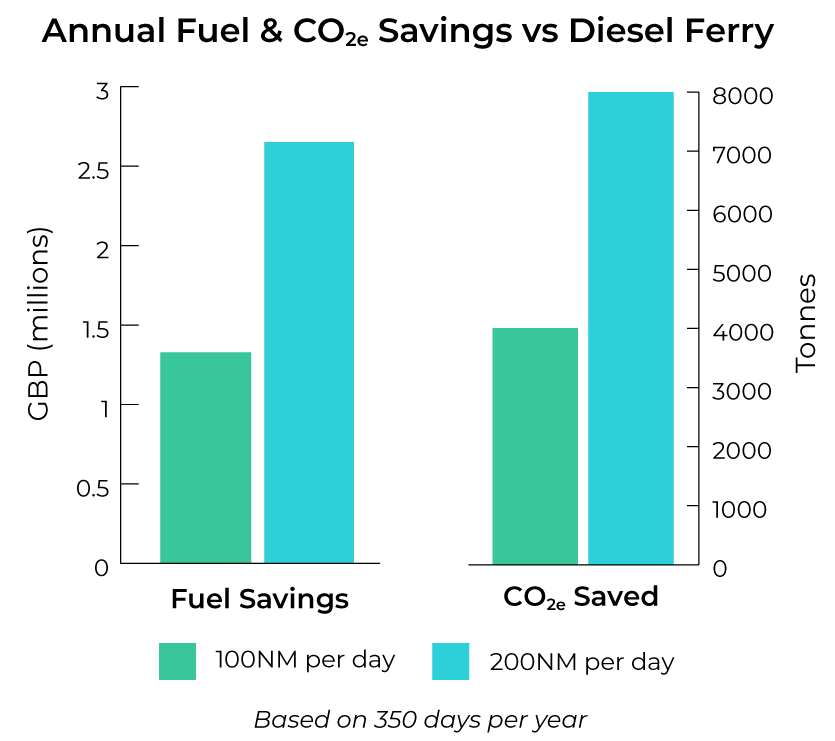

LOWER OPERATING COSTS - Comparison between the EF-24 Passenger ferry with a comparable diesel fuelled ferry. When operating at a 35 knots average cruise speed for 200 nautical miles per day, 350 days per year, fuel savings will amount to £2.6 million, whilst also preventing the release of 8,000 tonnes

CO2.

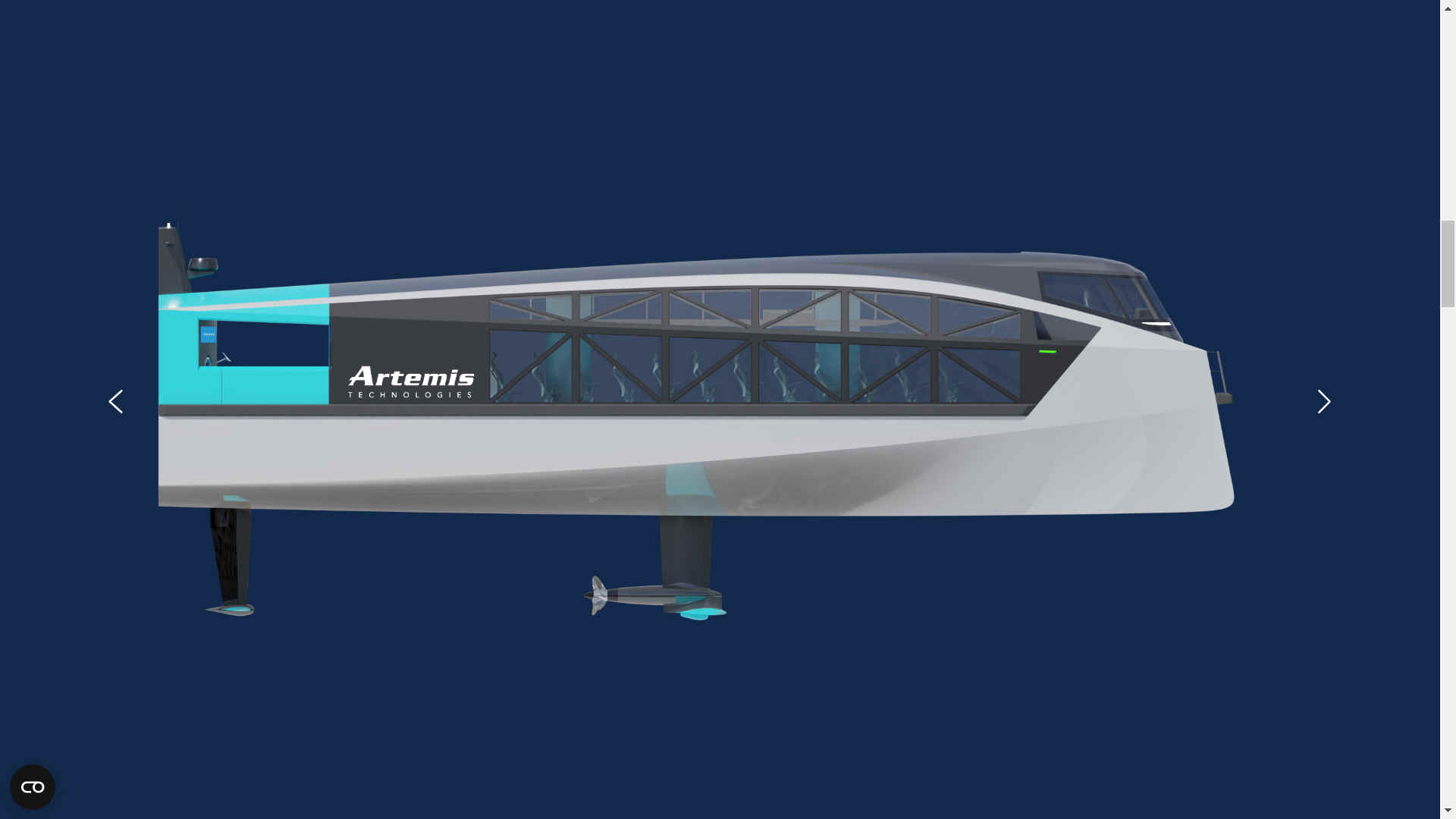

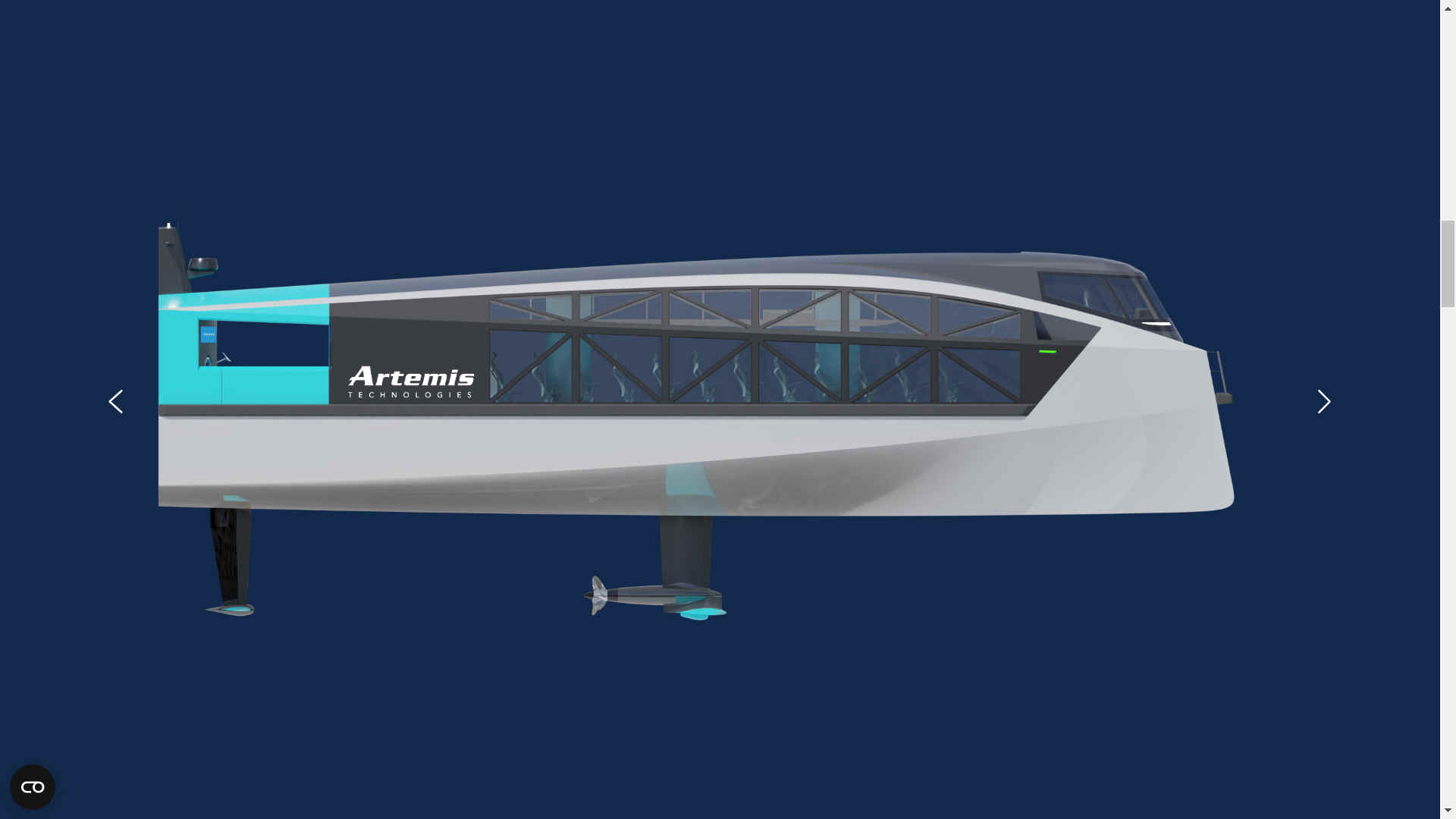

ARTEMIS ELECTRIC PASSENGER FERRY

Leading maritime design and applied technologies company Artemis Technologies has unveiled the design of its new 100% electric EF-24 Passenger vessel, targeting the global high-speed ferry market.

This revolutionary ferry is among several zero-emission vessels being developed by Artemis Technologies in Belfast, Northern Ireland, designed to provide commercially viable green transport solutions for operators, cities and governments across the world.

With a top speed of 38 knots, the EF-24 Passenger ferry offers a range of 115 nautical miles at a 25 knots cruise speed and produces incredible fuel savings of up to 85% compared to conventional high-speed diesel ferries.

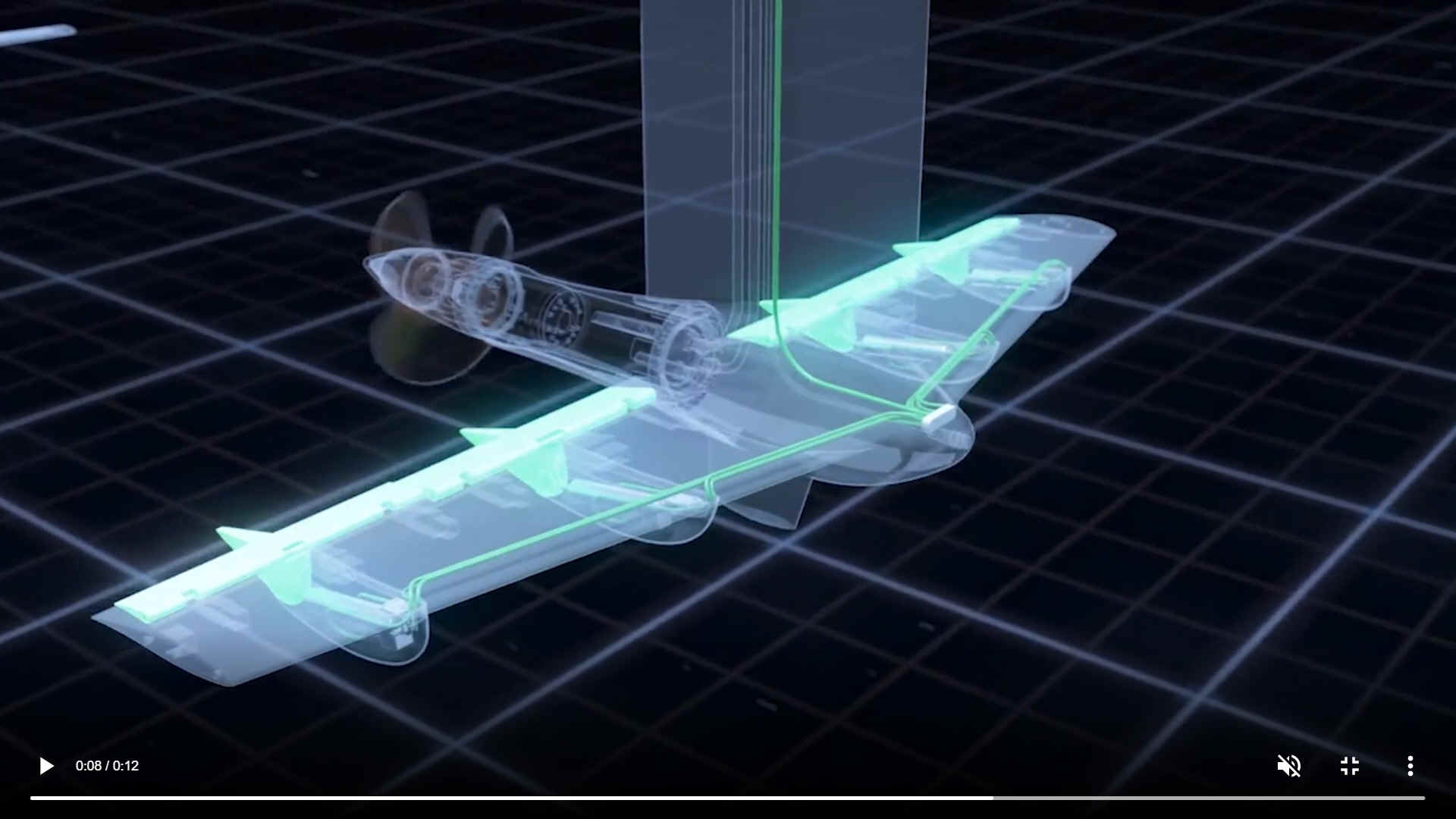

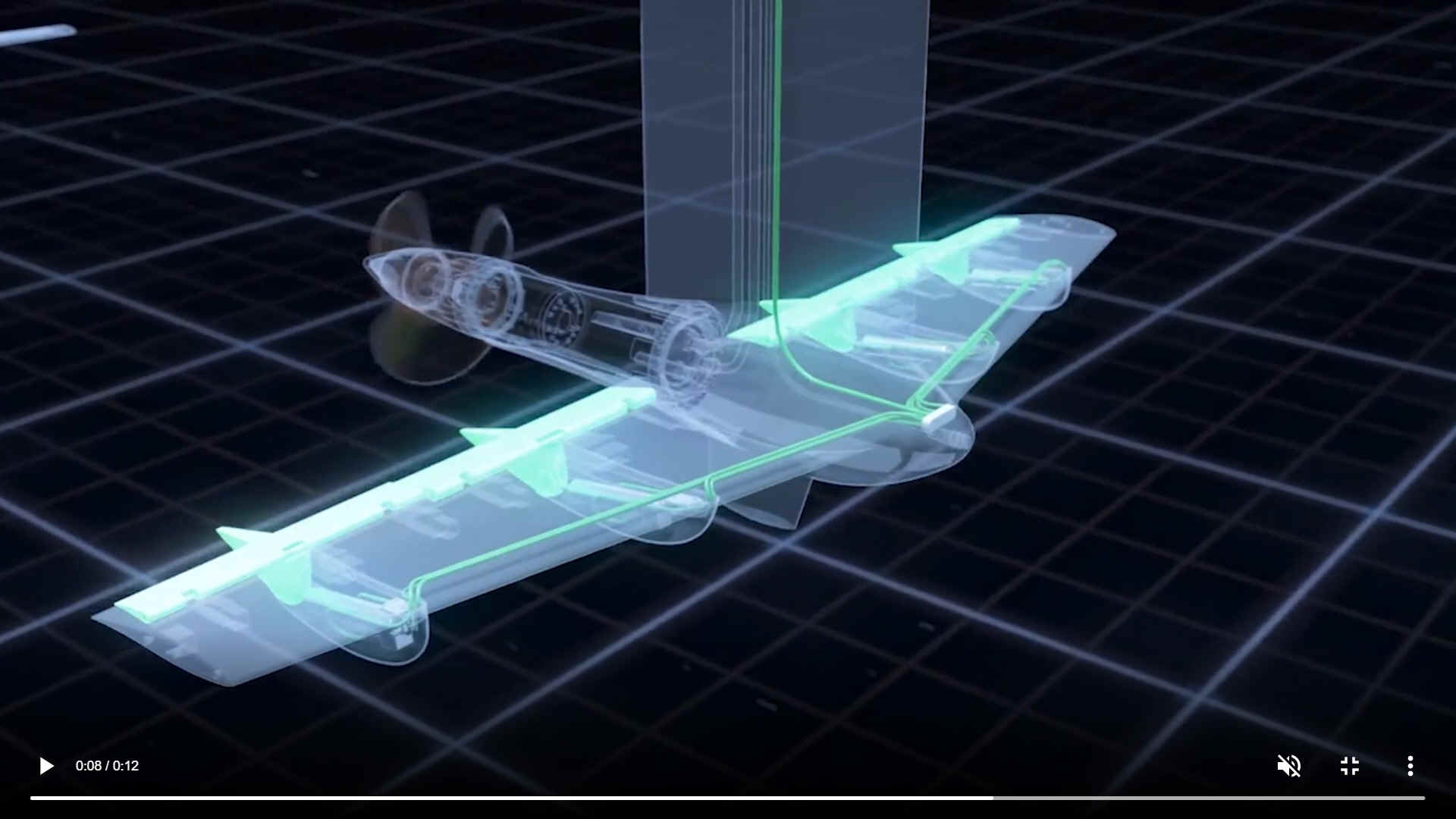

Powered by the patented Artemis eFoiler® electric propulsion system, the 24m vessels will fly above the water, providing a comfortable ride for up to 150 passengers on board, mitigating effects of seasickness and producing minimal wake at high-speed, significantly reducing the impact on shorelines.

Artemis Technologies is a spin-off from the Artemis Racing team that competed in the America’s Cup of which its founder, two-time Olympic champion Dr Iain Percy OBE is a four-time veteran. He said:

“We have combined our experience from the worlds of high-performance sailing, motorsports, aerospace, and advanced manufacturing to design and develop an electric propulsion system that is quite simply a game changer for the maritime industry.

“Our high-speed passenger ferry provides a cost-effective public transport solution that helps address air pollution, congestion, and noise.

“By encouraging multimodal transport in urban areas, we will enable cities around the world to utilise and benefit from the untapped potential of their waterways.

“With hydrofoils that lift the boats out of the water, we are dramatically reducing drag. This is coupled with a submerged electric drivetrain that is exceptionally efficient, as proven through rigorous testing with our 12m eFoiler® workboat, validating our digital simulations and performance prediction.”

The ferries will be fully accessible, incredibly spacious with a range of facilities on board including bike racks, cabin bag and overhead storage, baby changing facilities, and charging points.

The vessels will also feature a unique high-speed collision avoidance system developed with ECIT, part of Queen’s University Belfast. The system will ensure the safety of operations in port and close to shore by safely diverting the ferry on an altered path away from sea life, wildlife,

debris and other in-water objects that might otherwise be obscured from view.

Artemis Technologies has partnered with Condor Ferries to operate a pilot scheme using the first EF-24 Passenger ferry. This will come into service in 2024, running between Belfast and Bangor in Northern Ireland.

Iain added:

“The zero-emission ferry that will be seen departing Belfast in 2024, aptly named ‘Zero’, will be the first we build at our manufacturing hub in the city, but it is only the start.

“Many water-based cities around the world are grappling with the challenge of

growing

populations, congestion, and pollution.

“The EF-24 Passenger can provide an immediate green transport solution that competes economically with road and rail in places like San Francisco, New York, Venice, Istanbul, Dubai, and Singapore – anywhere around the globe that is seeking sustainable transport alternatives that balance the requirement for people to continue to move around with the need to reduce

carbon emissions.

“Especially where new infrastructure is required like a new road or rail line, this ferry will not only be the cheapest, but also the fastest and least disruptive way to decarbonise transport networks in water-based cities”.

John Napton, CEO of Condor Ferries, said:

“As a leading operator of passenger ferries, we continuously seek to explore technology that will allow us to sail more sustainably, and we know our customers are of the same mindset.

“Green vessels like the EF-24 Passenger ferry perfectly provide that clean alternative to traditional diesel ferries.

“We are thrilled to partner with Artemis Technologies and the Belfast Maritime Consortium to develop these vessels from concept to reality over the coming months and look forward to being the first operator to set sail in 2024 with the world’s most advanced zero-emission foiling fast ferry.”

Secretary of State for Northern Ireland Chris Heaton-Harris added:

“My congratulations to Artemis Technologies and Belfast Maritime Consortium on unveiling the plans for this exciting zero emissions vessel.

“I recently visited Artemis’ headquarters. I am delighted that they are seizing the many opportunities that the development of green transport presents, and which the UK Government is committed to supporting through our Net Zero Strategy.

“The development of such world-leading technology will ensure that Belfast remains at the forefront of maritime innovation, while providing a boost to the local

green

economy.”

Earlier this year on its continued mission towards the decarbonisation of maritime, Artemis Technologies launched the world’s largest 100% electric foiling vessel, ‘Pioneer of Belfast’ and unveiled an electric workboat range including a 12m multi-purpose workboat and a 12m crew transfer vessel with a 24m crew transfer vessel also currently under development.

Artemis Technologies is a spin-off from the Artemis Racing team that competed in the

America’s Cup of which its founder, two-time Olympic champion Dr Iain Percy OBE is a four-time veteran.

Dr Percy OBE is quoted as saying:

“Combining our experience from the worlds of high-performance sailing,

motor-sports and advanced manufacturing, the electric propulsion system that we’ve designed and developed is an absolute game changer for the industry in terms of range, costs savings and minimal wake created.

“With hydrofoils that lift the boats out of the water, we are dramatically reducing drag. This is coupled with a submerged electric drivetrain that is exceptionally efficient, as proven through rigorous testing with our partners, confirming what we had discovered through our own onshore digital simulations.

“The ride comfort of a hydrofoiling vessel through a large seaway has to be experienced to be believed, offering a completely smooth journey whatever the sea state.

“This will allow engineers in crew transfer vessels or port operations to get to their destination and deliver their services without discomfort.

“This is only the beginning. As our vessels transform the commercial workboat and city-to-city passenger ferry sectors over the coming years, Belfast and the UK will be at the forefront, creating thousands of jobs across the supply chain and heralding a green shipbuilding revolution.

“With the global small boat market worth $70 billion, we are immensely proud to launch our first range of

zero-emission vessels for the workboat sector, from which we have already received significant pre-market interest.

“This is a hugely significant milestone not only for us but in global decarbonisation efforts with the International Maritime Organization requiring emissions to be halved by 2050.”

Artemis Technologies’ full workboat range includes an 11.5M multi-purpose workboat and a 12M crew transfer vessel. A 24M crew transfer vessel is also currently under development.

The launch comes as a new Centre for Economics and Business Research

(CEBR) report, commissioned by Maritime UK, puts the economic impact of UK maritime at £116 billion. With Northern Ireland’s maritime industry directly contributing more than £2 billion to the UK economy, a bigger impact than Wales, Yorkshire and the Humber combined.

Maritime UK chair Sarah Kenny is quoted as saying:

“As an island nation, maritime surrounds all of us, and its impact is felt in every community across the UK.

“We saw that during the pandemic, through the provision of vital supplies, and we are seeing it now as we bounce back. With maritime driving the net zero agenda and providing skilled jobs in all corners of the country.

“Artemis Technologies’ launch today shows our heritage as maritime pioneers will continue long into the future. But continued collaboration with government, and investment, will be the key to

realizing our full potential.”

Secretary of State for Northern Ireland, The Rt Hon Brandon Lewis CBE is quoted as saying:

“The talent and expertise at Artemis Technologies is leading the way in maritime decarbonisation and playing an important role in helping Northern Ireland and the UK reach our Net Zero targets.

“Artemis is making a positive contribution to the UK’s economy, supporting innovation and job growth through the development of zero-emission technology.

“I am delighted that such amazing technology has been developed in Northern Ireland and to have been able to see the eFoiler technology up close during a recent showcase in Belfast.

“The launch of this range of green vessels by Artemis Technologies is a truly positive step in the fight against climate change.”

Leo Hambro, Commercial Director, at Tidal Transit, which operates a fleet of purpose-built offshore wind crew transfer vessels in waters around the UK and overseas said:

“Having worked closely with Artemis Technologies, as part of the UK Government’s Clean Maritime Demonstration Competition (CMDC), funded by the Department for Transport, today’s launch marks a sea-change in how workboat operators will view electric foiling boats.

“Given the remarkable range, incredible speed and comfortable ride, this workboat is truly a game-changer for our sector as it looks to cut carbon emissions across the industry.”

ARTEMIS CONTACTS

Head Office:

4th Floor, Concourse 2

Queens Road

Belfast

BT3 9DT

Manufacturing Facility & Goods In:

Unit 1 Oakbank

Channel Commercial Park

Queens Road

Belfast

BT3 9DT

REFERENCES

https://foilingguide.com/docs/how-do-hydrofoils-work/

https://www.artemistechnologies.co.uk/efoiler/

https://www.artemistechnologies.co.uk/ef-24-passenger-ferry/